24 gauge kynar 500 painted steel 0236 thickness prior to painting galvanized g 90 or zincalume az 50 per astm a 792.

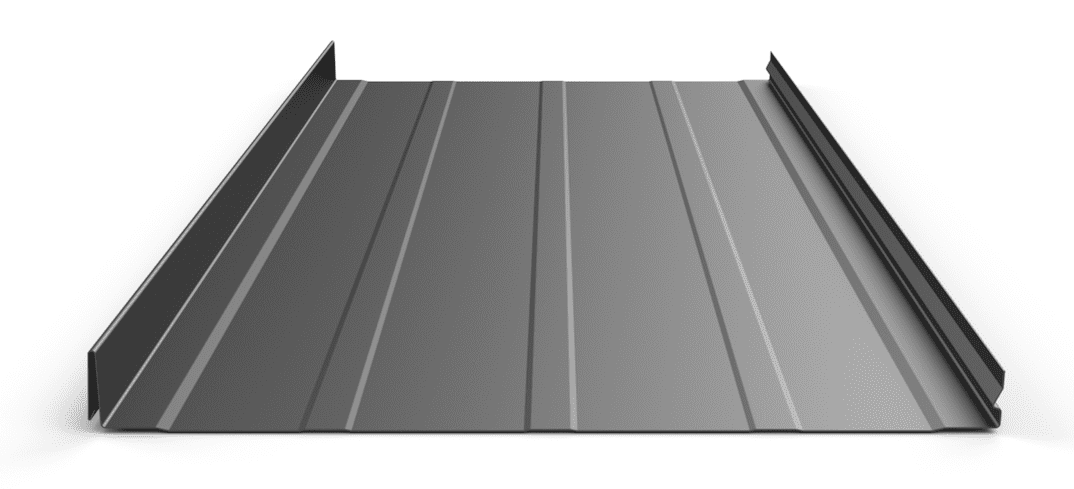

Roof 24 gauge kynar 500 painted steel 1 5 standing seam.

Kynar 500 is a paint system typically used on top of galvalume or galvanized steel or aluminum.

The ms 150 is a fully crimped standing seam roof that is perfect for high wind areas and snow country.

A standing seam panel is best used with aluminum or 24 gauge galvalume and provides the most maintenance free metal roof system available.

Kynar 500 based painted metal roofing can achieve solar reflectance of over 70.

Our standard is 24 gauge which withstands hail better than even the commonly accepted 26 gauge panels offered by most other metal roofers.

These metal roofing component manufacturers have chosen kynar 500 resin based coating for use in their roofing solutions due to its durability as well as its capability to retain color over long periods of time.

True standing seam will have concealed fasteners usually with clips which allow for expansion and contraction.

For over 50 years pvdf polyvinylidene fluoride has been the preferred metal roofing finish by building owners architects and contractors across america.

Standing seam roofs are generally made from thicker grades of steel than corrugated steel roofs.

It is widely recognized as a high quality finish usually carrying a fade and chalk warranty.

While many corrugated steel roofs are made using the thinner 29 gauge steel a minimum of 26 gauge g 90 galvanized steel or more commonly galvalume steel better is used for manufacturing of standing seam metal panels.

The metal coil that is rollformed into panels comes in many different thicknesses.

However standing seam panels are typically somewhere between 22 and 26 gauge with the most common galvalume steel thickness being 24 gauge and aluminum between 032 and 040 inches.

High seams high seam panels have a greater benefit versus a lower seam panel for moisture penetration.

Cool metal roofing coated with kynar 500 based resin is one way to limit the urban heat island effect.

Kynar 500 hylar 5000 pvdf metal roofing finishes.

A 24 and 22 gauge steel can also be used.

Urban heat island a built environment where the large portion of dark absorbing.

Features benefits of standing seam metal roofing.

While this is the standard for numerous stamped steel panels in the market that are created to look like slate or shake it is not the norm for true standing seam metal roofing material.